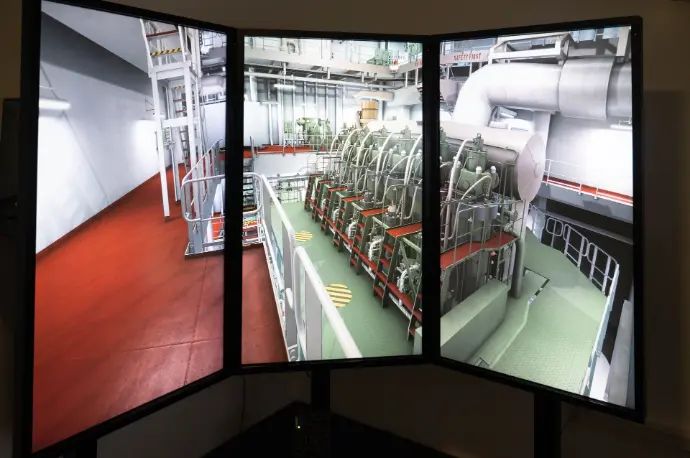

Wärtsilä ERS TechSim 9

Training objectives and capabilities of the Engine Room Simulator TechSim 9 include:

- Engine room familiarization and operations

- Electrical power plant control and balance

- Automation, alarm and safety system response

- Fuel economy and emission monitoring

- Emergency operations, fault diagnosis and troubleshooting

- Watchkeeping and resource management

Multiple deployment modes

- Solo mode on individual workstation

- Networked mode with multi-station coordination

- Full mission mode with integrated engine-bridge CRM scenarios

Instructor interface includes advanced exercise design, monitoring, recording, debriefing, evaluation and communication tools.

Unitest ERS LNG-DE3D

Our Unitest Engine Room Simulator LNG-DE3D's training scope and features include accurate simulations of typical vessel engine room layouts including controls, gauges, alarms and system interlocks.

Fault introduction and diagnostics come with mixable, real-time faults across systems. Operational routines training include starting and stopping machinery, valve and pump operations and system balancing.

Deployment modes include solo, networked and full mission mode with integrated engine-bridge CRM scenarios. Instructor interface includes advanced exercise design, monitoring, recording, debriefing, evaluation and communication tools.

Engine models/STCW competences

Engine models:

- MAN B&W 6S60MC-C Diesel Engine - Tanker LCC

- Wärtsilä V46F Diesel-Electric Royal Princess

- MAN B&W ME-C Cam-Less Electronic Engine - Containership

- ANZAC 2 Frigate

- Chemical Tanker

- LNG Bunkering

- LPG Tanker

STCW competence:

- Table A-III/1.1 Maintain a safe engineering watch

- Table A-III/1.3 Use internal communication systems

- Table A-III/1.4 Operate main and auxiliary machinery and associated control systems

- Table A-III/1.5 Operate fuel, lubrication, ballast and other pumping systems and associated control systems

- Table A-III/1.6 Operate electrical, electronic and control systems Maintain seaworthiness of the ship

- Table A-III/1.11 Maintain seaworthiness of the ship

- Table A-III/2.1 Manage the operation of propulsion plant machinery

- Table A-III/2.2 Plan and schedule operations

- Table A-III/2.3 Operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery

- Table A-III/2.4 Manage fuel, lubrication and ballast operations

- Table A-III/2.5 Manage operation of electrical and electronic control equipment

- Table A-III/2.8 Detect and identify the cause of machinery malfunctions and correct faults

- Table A-III/2.10 Control trim, stability and stress

- Table A-III/2.11 Monitor and control compliance with legislative requirements and measures to ensure safety of life at sea and protection of the marine environment

- Table A-III/2.14 Use leadership and managerial skills

- Table A-III/4.2 For keeping a boiler watch: Maintain the correct water levels and steam pressures

- Table A-III/6.1 Monitor the operation of electrical, electronic and control systems

- Table A-III/6.2 Monitor the operation of automatic control systems of propulsion and auxiliary machinery

- Table A-III/6.3 Operate generators and distribution systems

- Table A-III/6.4 Operate and maintain power systems in excess of 1,000 Volts

- Table A-III/6.5 Operate computers and computer networks on ships

- Table A-III/6.6 Use internal communication systems

Engine models:

- RT-Flex50DF

- W-X35

- W-X62

- W-X72

- W-X72DF

- W-X92

- W-X92DF

STCW competence:

- Table A-III/1.1 Maintain a safe engineering watch

- Table A-III/1.4 Operate main and auxiliary machinery and associated control systems

- Table A-III/1.5 Operate fuel, lubrication, ballast and other pumping systems and associated control systems

- Table A-III/1.6 Operate electrical, electronic and control systems Maintain seaworthiness of the ship

- Table A-III/1.11 Maintain seaworthiness of the ship

- Table A-III/2.1 Manage the operation of propulsion plant machinery

- Table A-III/2.2 Plan and schedule operations

- Table A-III/2.3 Operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery

- Table A-III/2.4 Manage fuel, lubrication and ballast operations

- Table A-III/2.5 Manage operation of electrical and electronic control equipment

- Table A-III/2.8 Detect and identify the cause of machinery malfunctions and correct faults

- Table A-III/2.11 Monitor and control compliance with legislative requirements and measures to ensure safety of life at sea and protection of the marine environment

- Table A-III/4.2 For keeping a boiler watch: Maintain the correct water levels and steam pressures

- Table A-III/6.1 Monitor the operation of electrical, electronic and control systems

- Table A-III/6.2 Monitor the operation of automatic control systems of propulsion and auxiliary machinery

- Table A-III/6.3 Operate generators and distribution systems

- Table A-III/6.4 Operate and maintain power systems in excess of 1,000 Volts

- Table A-III/6.5 Operate computers and computer networks on ships